1. What are material pairings?

Material pairings occur in all areas of daily life and are characterized by the fact that the materials are in direct contact with each other and exert a corresponding force on each other. If now they also exert a relative motion to each other by oscillation, vibration or displacement, a friction between them is created.

Material pairings occur in all areas of daily life and are characterized by the fact that the materials are in direct contact with each other and exert a corresponding force on each other. If now they also exert a relative motion to each other by oscillation, vibration or displacement, a friction between them is created.

This effect belongs to the science of tribology. Friction depends on temperature, speed and pressure and also on material and surface properties. Thus, the basic conditions for stick-slip are also fulfilled, and this can lead to annoying noises and/or malfunctions. In any case, these effects due to annoying noises reduce the subjective quality of a product.

2. Which problems (challenge) do material pairings entail?

Product developers not only face the challenge of considering practicality, ease of use, product safety and costs. Today, it is also very important to consider the subjectively perceived quality when manufacturing products. It is influenced by the touch perception (haptics) and also by whether a product emits crackling noises, creaking noises or other annoying noises, caused by incompatible material pairings. Here, it is important to either decouple materials that can potentially come into contact with each other and still have a high stick-slip risk or to eliminate the relative movement.

In numerous cases this is not possible. Therefore, it is important to select material pairings that are non-critical, i.e., do not show stick-slip under any conditions. For this purpose, we have developed a material database that enables developers to select material pairings in advance that are non-critical to each other. The information in the database is based on measurement data collected with the ZIEGLER stick-slip test rig under real climatic and mechanical conditions. The database contains information on test temperature, humidity, contact force and relative speed as well as surface structure, surface coating and surface treatment. Since this represents a preselection, to be sure, the materials should be subjected to a material pair testing for stick-slip behavior.

3. How can I check material pairings?

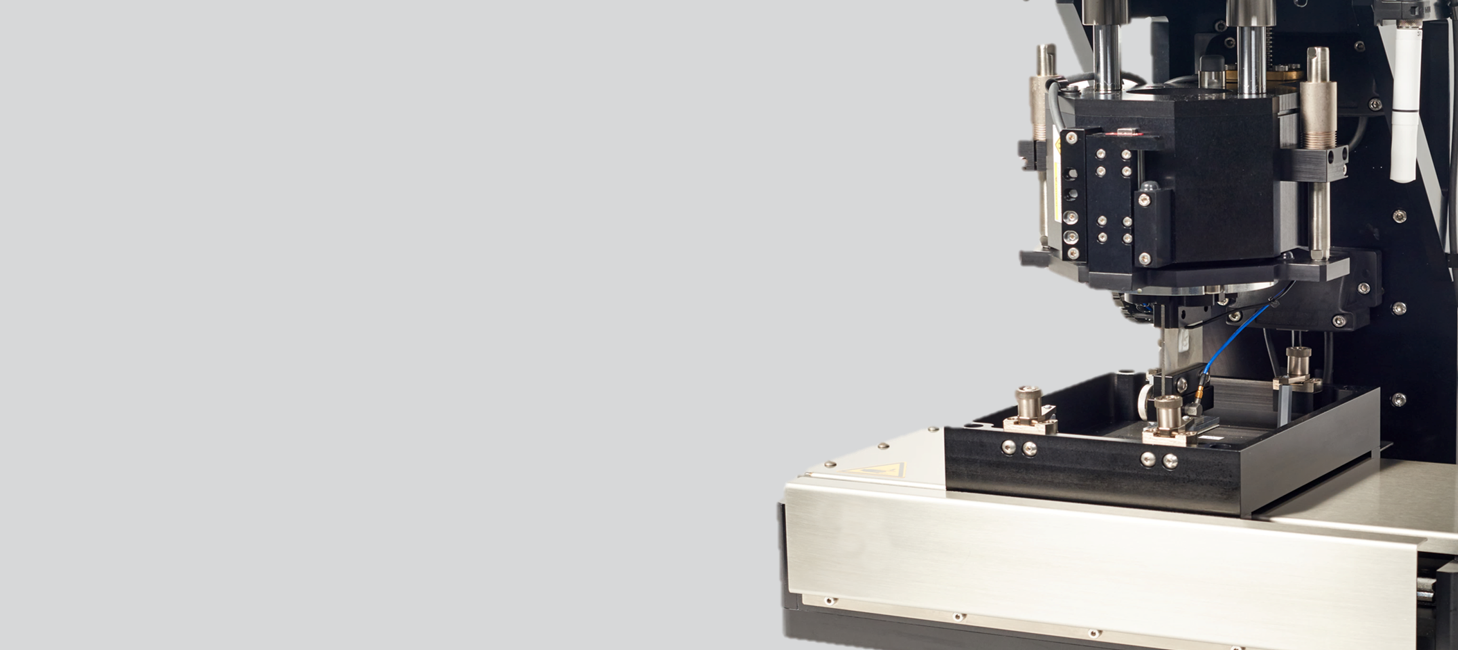

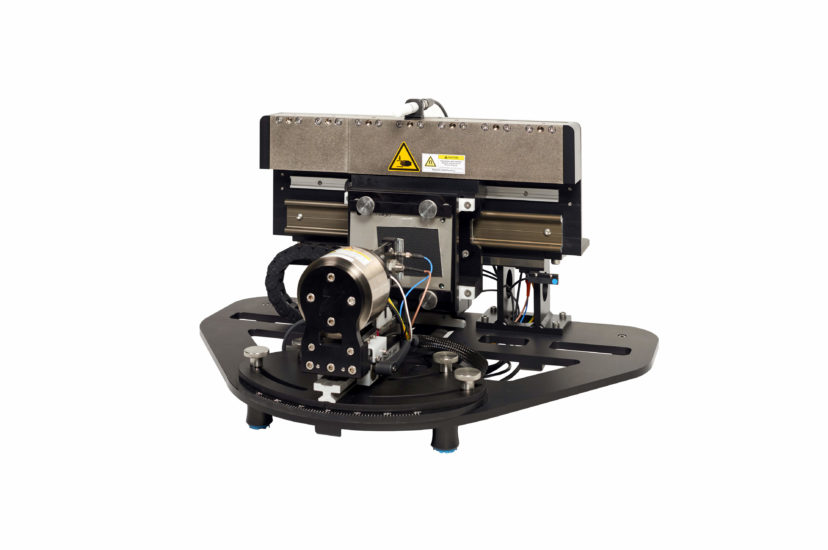

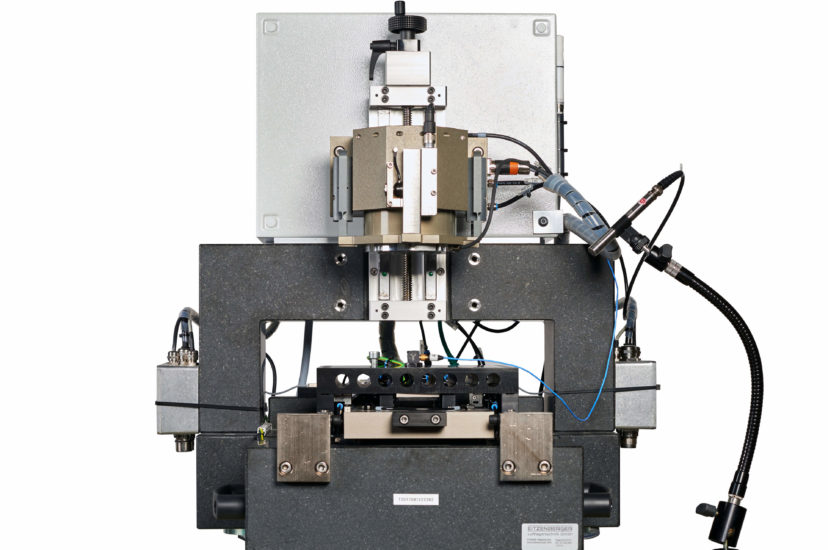

The occurrence of stick-slip phenomena when using certain materials can be attributed either to contact points with incompatible material combinations or to the influence of third-party substances. Our test institute can use its SSP-04 and H3P stick-slip test rigs to make predictions about possible stick-slip effects and the associated creaking problems.

The occurrence of stick-slip phenomena when using certain materials can be attributed either to contact points with incompatible material combinations or to the influence of third-party substances. Our test institute can use its SSP-04 and H3P stick-slip test rigs to make predictions about possible stick-slip effects and the associated creaking problems.

The performance of stick-slip measurements provides indications of critical material combinations and the influence of third-party materials that reduce the objective quality of the product due to abrasion and wear. Therefore, the durability test we have developed is of great importance. It is a test, developed on the basis of real road profiles.

4. Our services for you

We are specialized in performing problem-oriented stick-slip tests as a service. Based on our 25 years of experience in the prevention and reduction of annoying noises, we can transfer real problems into the laboratory by individual test procedures and thus make them reproducible. These are the basic prerequisites for investigating the core cause and subsequently finding a solution.

We are specialized in performing problem-oriented stick-slip tests as a service. Based on our 25 years of experience in the prevention and reduction of annoying noises, we can transfer real problems into the laboratory by individual test procedures and thus make them reproducible. These are the basic prerequisites for investigating the core cause and subsequently finding a solution.

On this basis, new findings about materials often emerge, which we then develop into new test methods. These in turn flow into the development of new testing technologies.

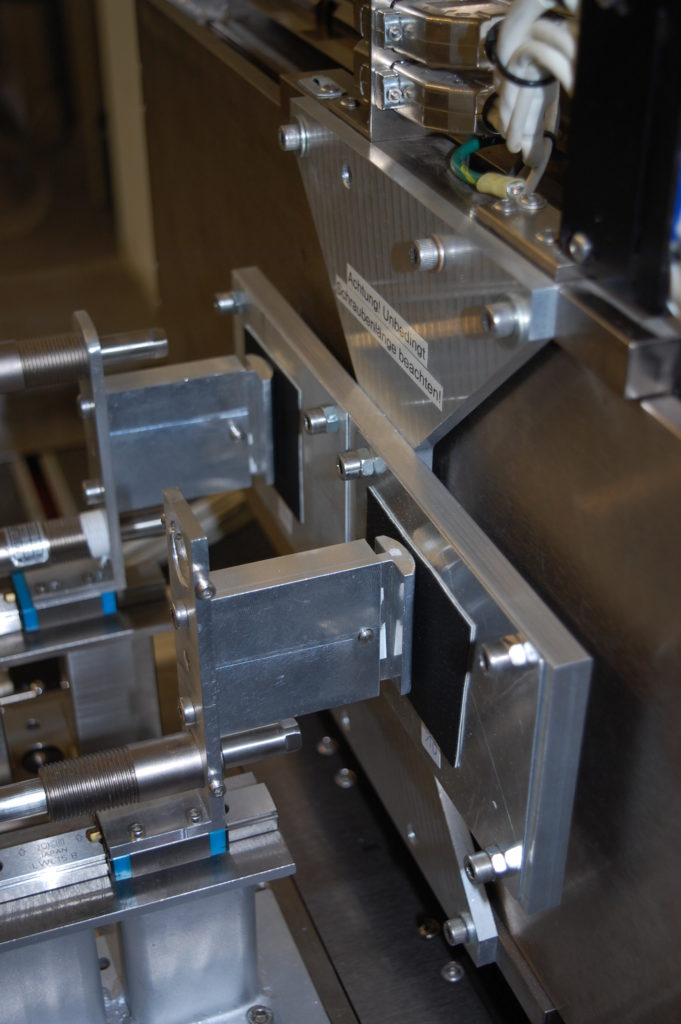

The objective of the above-mentioned KOREMA test rig, which is characterized by its extremely low operating noise, is noise testing of textiles. Under realistic motion profiles, we use highly sensitive measuring microphones to measure friction noise and evaluate it according to its degree of disturbance.

5. Examples of material pair tests

| Material A | Material B | |

|---|---|---|

| Leather/artificial leather | Leather/artificial leather | |

| Leather/artificial leather | Hard plastics of any kind | |

| Chrome-plated plastics | Leather/artificial leather | |

| Chrome-plated plastics | Painted and unpainted plastics | |

| Painted and unpainted plastics | Painted and unpainted plastics | |

| Foams | KTL-Beschichtung | |

| Seals | Glass | |

| Seals | Painted sheet metal | |

| Textiles | Anodized aluminium | |

| Textiles | Painted and unpainted plastics | |

| Steel | Steel (with and without lubricants) | |

| Plastics | Plastics (with and without lubricants) |

6. Touch haptics

6.1 What do I understand by touch haptics?

Touch haptics means the perception caused by touching materials and surfaces. Determined properties are surface texture, compliance, temperature, thermal conductivity etc. of a surface.

Haptics refers to both the teaching of haptic perceptions and the haptically perceivable object properties, e.g. as an aspect of ergonomics.

We are focused on the touch-haptic perception of materials and surfaces.

6.2 How can I measure touch haptics?

Assuming that our sense of touch, i.e. haptics, significantly influences our purchasing decisions, our research has been geared towards making an objectifiable haptic fingerprint measurable for many years. We succeeded in breaking down touch-haptic perceptions to clearly defined physical properties.

These are:

- Macro-roughness (visible surface structures)

- Micro-roughness (non-visible surface structures)

- Touch temperature

- Hardness/softness

- Jerk-slip (Stick-Slip)

- Slipperiness

In order to unambiguously define each physical property in terms of language, we have keyworded them and named them with descriptors. Here we used the Senso-Tact scale, which rates each descriptor on a scale from 1 to 100. Each measured property was correlated to this scale for this purpose.

For touch temperature, for example, the scale for aluminium has a 100, since this element feels very cold to the touch. Styrofoam, on the other hand, was given a 1 because it feels very warm to the touch.

6.3 What services do we offer?

We offer the metrological acquisition of the touch haptic fingerprint based on the above-mentioned physical properties of almost all solid materials. With the help of this haptic fingerprint we are able to compare materials and surfaces with each other, e.g. with a reference.

6.4 Examples of touch haptics

In our physics laboratory we can objectively determine the touch haptic fingerprint on almost all materials of daily life.

These are for example:

These are for example:

- Leather and imitation leather

- Packaging materials

- Plastics

- Softtouch coatings on plastics as well as leather and imitation leather

- Cooltouch coatings on plastics

- Paper

- Alcantara

- Metal sheets painted and unpainted