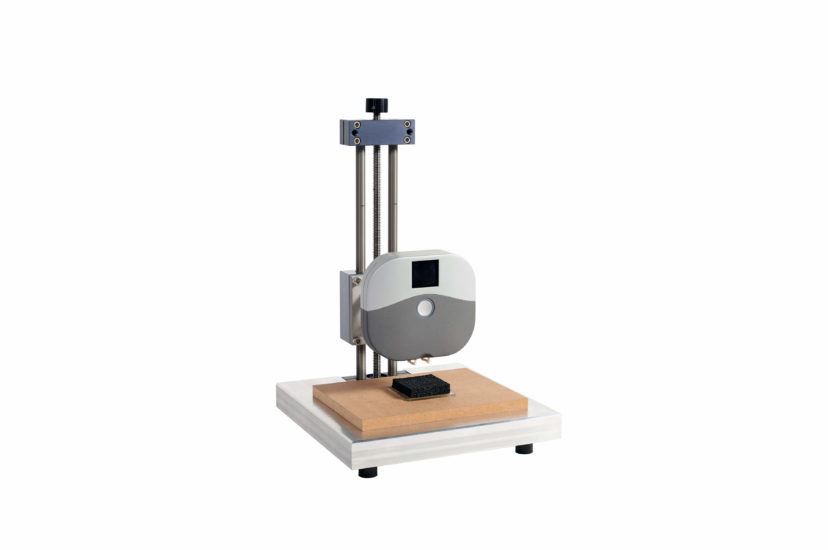

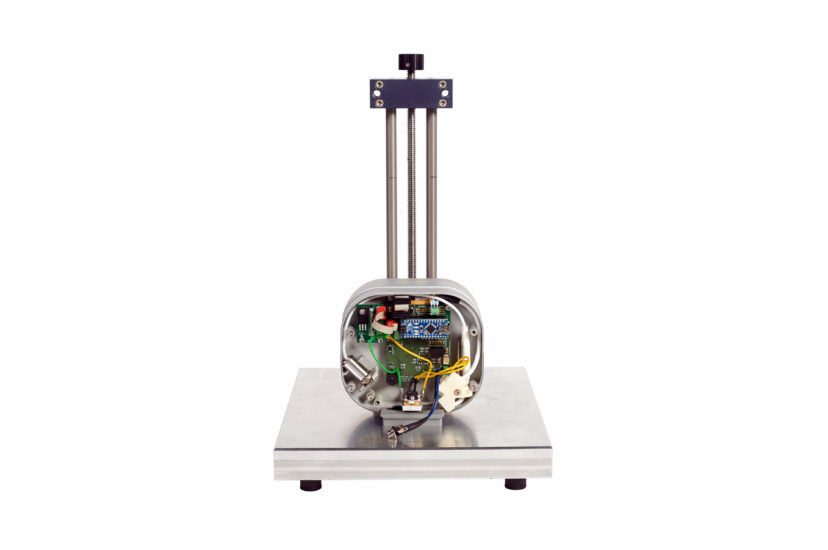

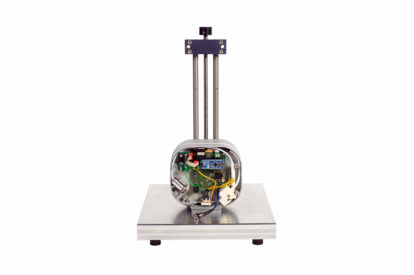

Measuring device for determining the perceived contact temperature

Would you like more information?

We are happy to help you!

- Determination of values that correspond to the scale of the TouchFeel Box.

- Determination of a value on the Sensotact scale for better comparability.

- Evaluation of the perceived touch temperature of a surface, e.g. in the context of marketing decisions

The touch temperature is closely related to perceived quality. When touching a material surface, we humans have a certain expectation of the surface temperature.

If the eye signals that a material is probably steel, then we expect a surface temperature corresponding to the material. If the haptic feedback does not correspond to the expectation, because the button of a stereo system, for example, is not made of steel but of coated plastic, then a cognitive dissonance occurs.

This results in confusion and in a reduced subjective impression of quality. This example can be applied to many control elements, such as a PC keyboard, artificial leather, door knobs, decorative elements in the car and many more.

By knowing the absolute values of the haptic touch temperature, the perceived quality can be influenced. This is possible with the HapTemp by a simple and fast measurement.

Therefore, studies with distorted results are no longer necessary. The measurement result is independent of transparency, gloss or color of the materials. HapTemp generates an absolute value in the Sensotact® scale. This scale correlates with the human sensation of the touch temperature.

By knowing absolute values, HapTemp provides information on the perceived touch temperature of a surface. Product managers thus have the opportunity to positively influence the perceived perception before series production and thus avoid cognitive dissonances that can lead to customers making a negative purchase decision.

- ›Shorter development times

- ›No subjective studies are needed anymore

- ›Optimization of subjective product quality

- ›Objective, repeatable measurement result