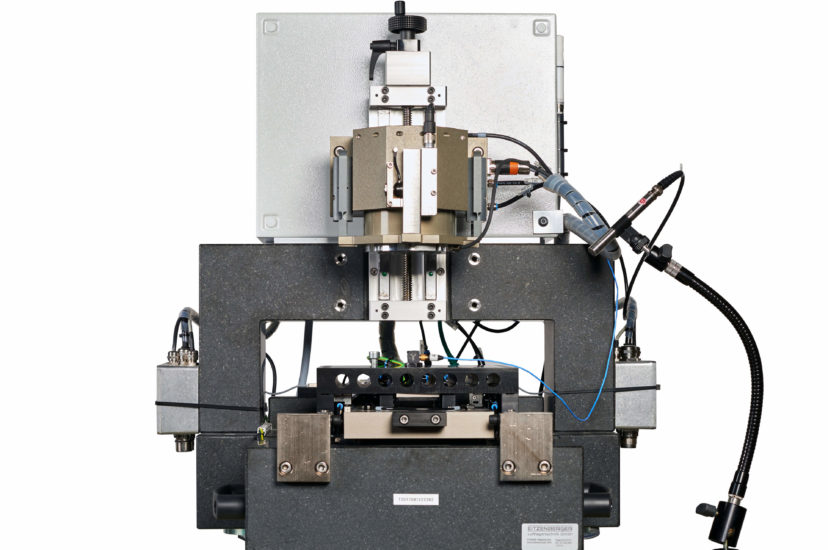

The test stand H3P is especially designed for the measurement of stick-slip effects under the influence of third substances, which influence the tribological system, such as oils, greases, fuels, coolants, water, pastes or dusts.

The influence of third substances on the tribological properties of materials, such as static friction, dynamic friction, stick-slip as well as abrasion and wear, is considerable and can possibly lead to malfunctions.

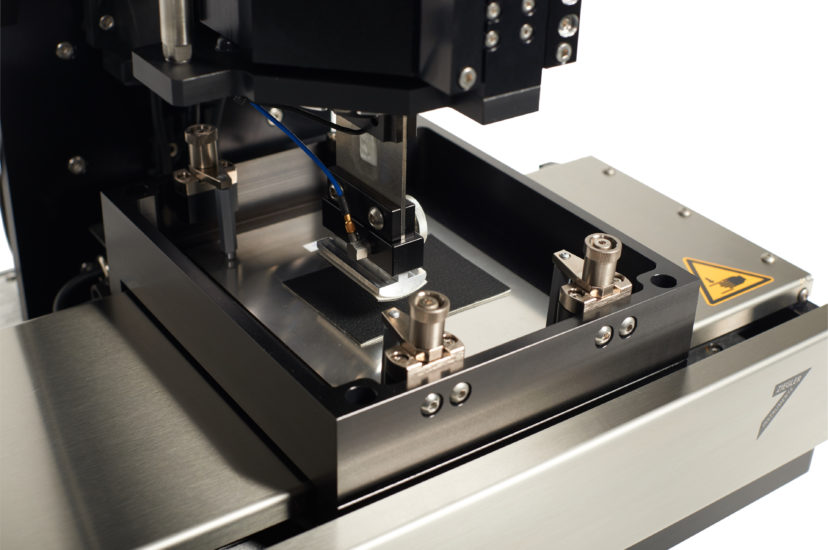

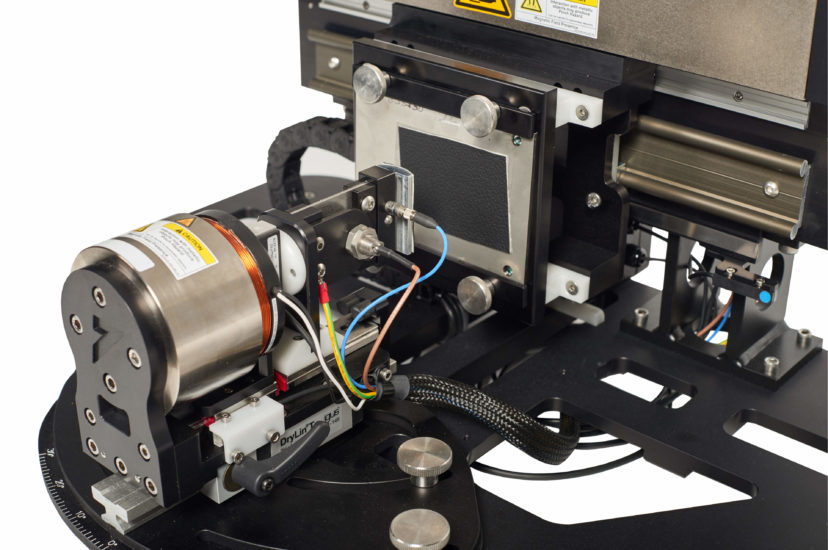

The SSP-04 is especially designed to measure the stick-slip effect of a material combinations with the help of an acceleration sensor under typical application conditions. In addition, the static and dynamic coefficient of frction are measured.

Noise phenomena caused by critical material combinations are often perceived as unpleasant and reduce the subjective quality of a product. In addition, stick-slip can lead to increased abrasion, wear and malfunction.

Through acoustic parameterization, Korema can correlate the psycho-acoustic effect of friction noises on the human perception and qualify it in the form of a degree of disturbance.

This knowledge is very useful for developing optimal material pairs for textiles. Those combinations are perceived as pleasant by the customer and thus increase the subjective product quality.