Test bench to investigate stick-slip effects of material combinations

Would you like more information?

We are happy to help you!

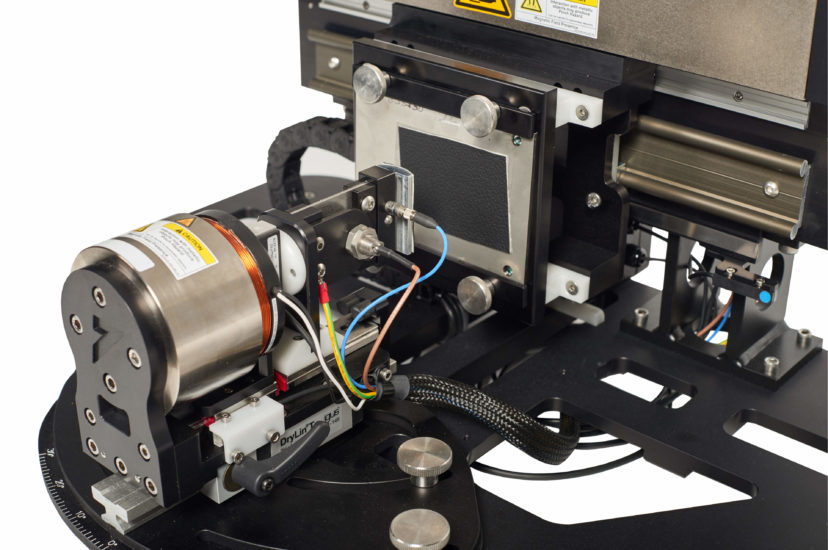

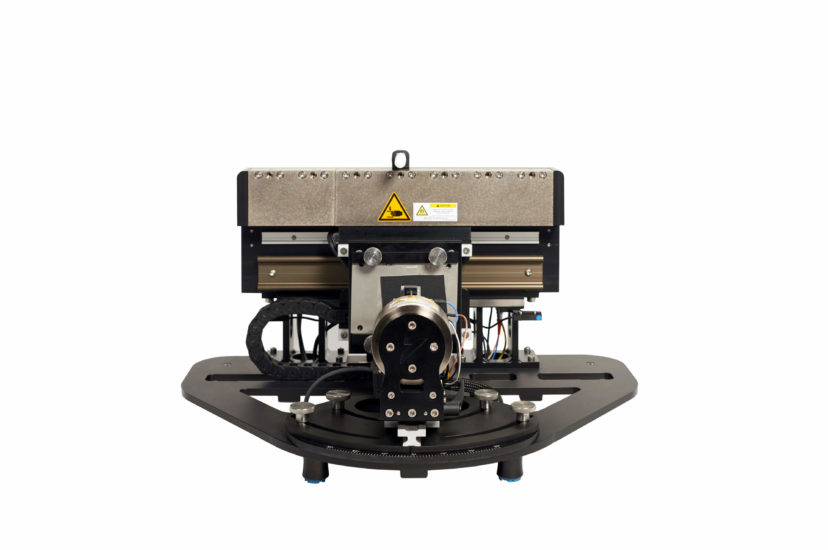

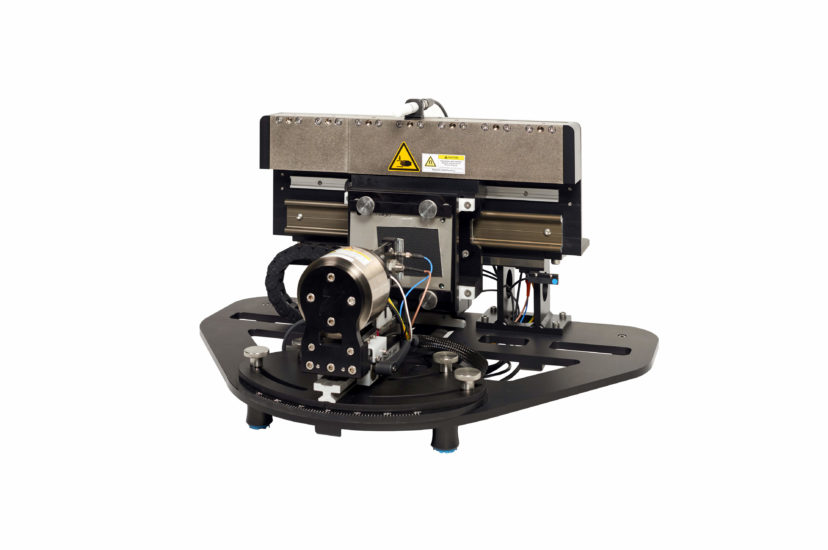

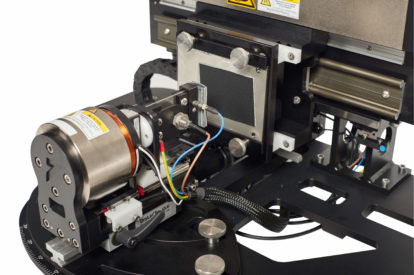

The SSP-04 is especially designed to measure the stick-slip effect of a pair of materials using an accelerometer under typical application conditions. In addition, the classical friction coefficients are determined.

Tribo-acoustics deals with noise phenomena which are caused by critical combinations of materials. These are often perceived as unpleasant and reduce the subjective quality of a product. In addition, stick-slip can lead to increased abrasion, wear and malfunction.

The risk priority number [RPN] is a reliable indicator of whether a material combination has a tendency of emitting creaking or squeaking noise.

This is helpful when developing new products and take appropriate countermeasures in early phases. Ideally, before selecting the material combinations and starting serial production.

Stick-slip measurements are already done for many years, especially in the automotive industry and are included in various test specifications. The SSP-04 complies with the VDA-230-206 as well as the test specifications of well-known OEMs such as BMW, Ford, Volkswagen, Toyota, Fiat, Jaguar Land Rover and many other manufacturers.

The SSP-04 determines critical material combinations that later diminish the objective quality of the product in the form of increased abrasion, wear and even malfunction. In addition, these material pairings also reduce the subjective quality of a product due to unwanted noises.

- ›Shorter development times

- ›Increase in product quality

- ›Callback Avoidance

- ›Reduction of warranty costs

- Evaluation of any material combination to measure their potential for squeaking noises

- Measurement of the elastic-plastic behaviour of components (e.g. seals)

- Simulation of mileage driven e.g. 100.000 km to determine the abrasion behaviour of coatings or surfaces.