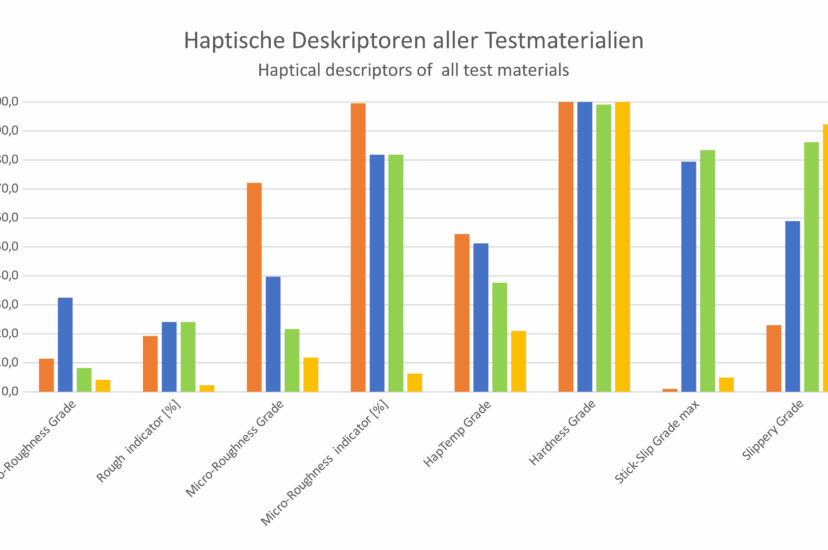

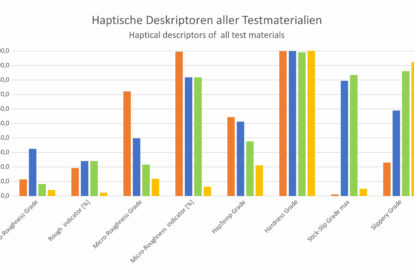

Example of a haptic fingerprint using 4 different material combinations

Would you like more information?

We are happy to help you!

The following examples illustrate the differences of different materials.

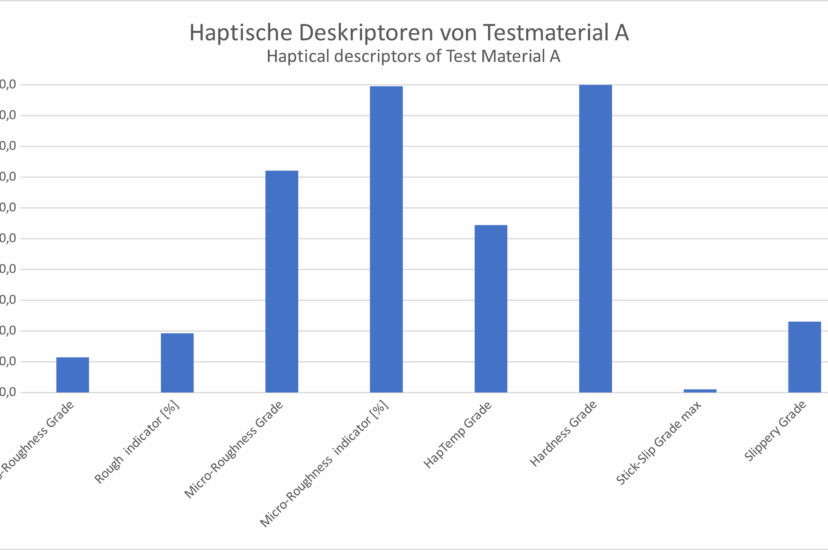

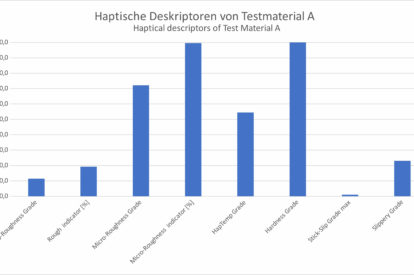

Material A

This material is an artificial leather. to the eye already a structure is recognizable, which allows conclusions about the haptic experience. However, only with the measurement results a reproducible and objective image is possible.

This material is an artificial leather. to the eye already a structure is recognizable, which allows conclusions about the haptic experience. However, only with the measurement results a reproducible and objective image is possible.

In practice, this can mean, for example, that in the production of artificial leather seats for passenger cars a very specific effect can be achieved, if the parameters are known. So the slippery factorcan be decisive for the purchase decision, the seats should be designed for a pleasant sitting feeling not too “slippery”, but also not too “sticky”.

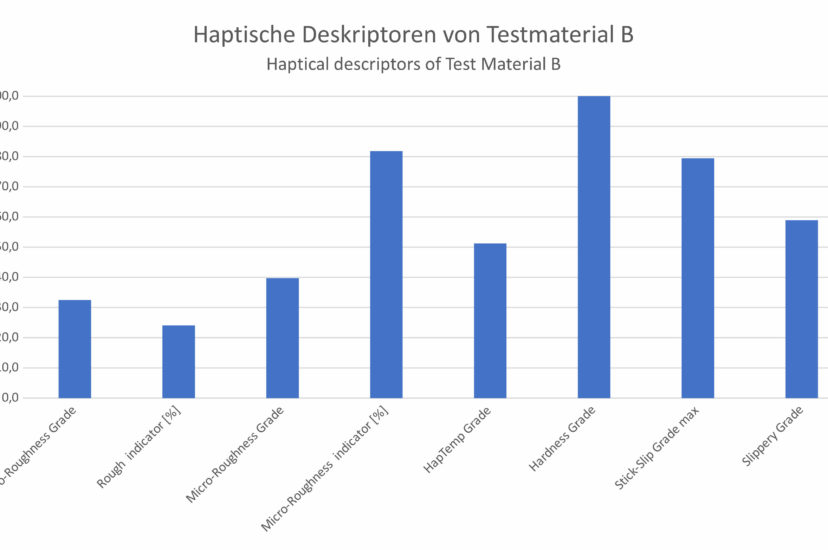

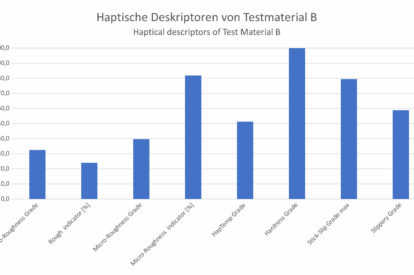

Material B

It is already visible that this artificial leather has a different structure. The measurement results are correspondingly different compared to material A. For our customers, exactly this measurement reliability is so important and useful, because a pure eye diagnosis can be useful in the practical implementation never cover the descriptors of our measurements – we would like to remind at this point once again that every person is different perceives.

It is already visible that this artificial leather has a different structure. The measurement results are correspondingly different compared to material A. For our customers, exactly this measurement reliability is so important and useful, because a pure eye diagnosis can be useful in the practical implementation never cover the descriptors of our measurements – we would like to remind at this point once again that every person is different perceives.

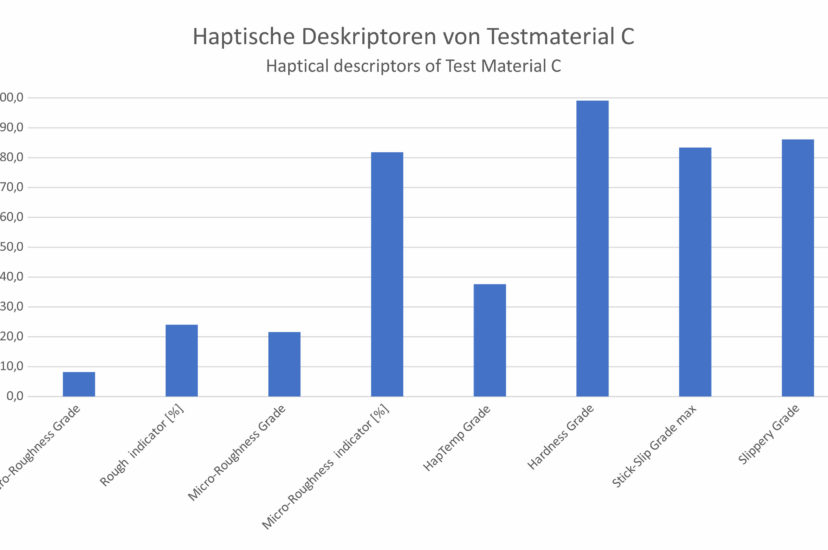

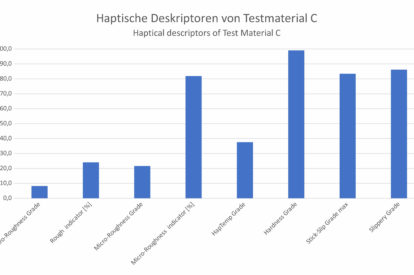

Material C

This much smoother imitation leather “tells” a different story again. The eye already perceives a relatively smooth surface, and the Measurement results confirm this: the macro roughness is in a very low measuring range.

This much smoother imitation leather “tells” a different story again. The eye already perceives a relatively smooth surface, and the Measurement results confirm this: the macro roughness is in a very low measuring range.

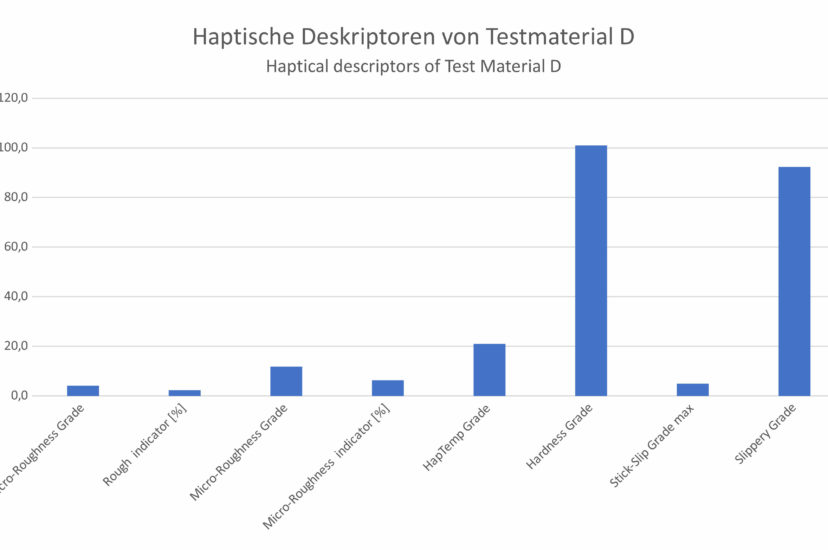

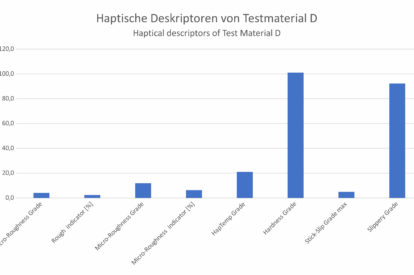

Material D

This material is completely different from those examined before. It is a very smooth surface, which is used for food packaging. The measurements show which macro- and micro-roughness must be given to achieve such a haptic experience. Thus our customer can choose the chemical ingredients as long as the measured values correspond to our measurement.

This material is completely different from those examined before. It is a very smooth surface, which is used for food packaging. The measurements show which macro- and micro-roughness must be given to achieve such a haptic experience. Thus our customer can choose the chemical ingredients as long as the measured values correspond to our measurement.

These four examples from our daily practice illustrate how essential the acquisition of surfaces for the process of product developments are. At this point we would like to once again emphatically point out that with the help of the haptic fingerprint it is possible to combine materials and surfaces with each other and compare it with a reference, for example. However, an absolute evaluation is currently not yet in our offer.