As a chemist dedicated to functional additives for automotive interiors, I help transform cabin materials into safer, cleaner, and more pleasant experiences from the molecular level up. With the growing use of advanced chemistries in interior components, processing and material by-products—such as certain aldehydes—can pose risks to human health and create undesirable sensory effects, especially unpleasant odors. Our Anti-Harmful agent series is engineered to mitigate or eliminate these issues with science-driven, regulation-ready solutions.

Positioning and value

Core mission: Reduce or remove harmful trace species (e.g., free formaldehyde, other aldehydes/ketones, low-molecular amines/sulfur compounds) and their odor impact, enabling low-VOC, low-fog, comfortable cabins.

Target applications: Interior plastics, PU foams, textiles and carpets, adhesives/sealants, leather and synthetic leather, NVH and insulation materials.

Compliance focus: Supports OEM VOC/fogging targets and test pathways such as VDA 270/VOC, GB/T 27630, ISO 12219, and related regional standards.

Technology highlights

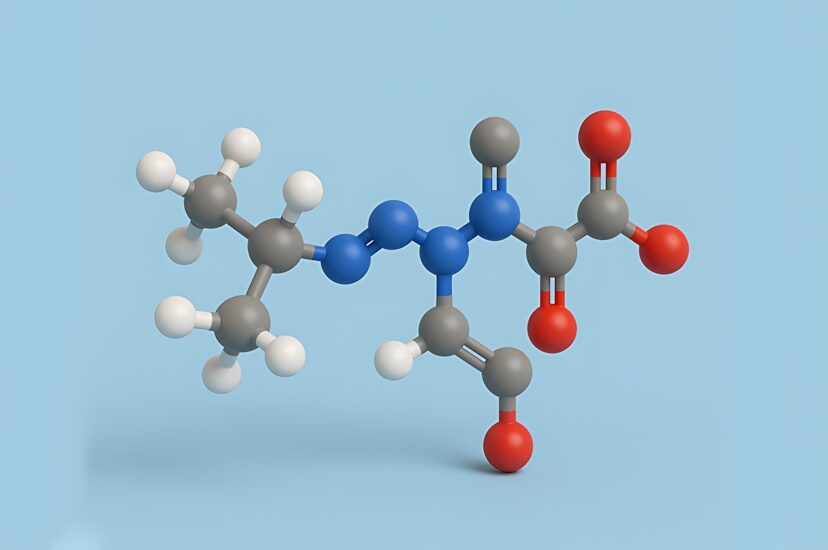

Selective capture chemistry: Tailored reactive sites efficiently bind free aldehydes and nitrogen/sulfur odorants into stable, non-volatile products (irreversible or low-volatility complexes).

Multi-mode purification: Chemical fixation + physical adsorption + catalytic conversion for longer-lasting control and reduced emission peaks.

Process-ready formats: Powder, masterbatch, and dispersion forms compatible with extrusion, injection molding, foaming, coating, lamination, and post-treatment spraying.

Robust and safe-in-use: Excellent thermal and shear stability; non-migratory and non-bleeding; preserves substrate mechanics and appearance.

Quantified benefits

Formaldehyde/acetaldehyde reduction: up to 50–90% (material- and process-dependent)

Overall VOC reduction: up to 30–70%

Odor grade improvement: typically +1 to +2 VDA 270 grades

Durability: sustained performance for ≥12–24 months under in-cabin conditions

Application pathways

Built-in at formulation: Integrate Anti-Harmful agent masterbatch/additive for in situ purification and long-term stability.

End-of-line refinement: Coating or post-treatment to rapidly lower early emission peaks and perceived odor.

Synergistic packages: Combine with adsorptive fillers (activated minerals, carbons) or low-odor bases for ultra-low VOC solutions.

What we provide

Selection and co-development: Tailored sub-series by reactivity, polarity, and particle size to match your substrate and process.

Lab validation: Rapid VOC/carbonyl quantification, odor panel assessments, thermal emission profiling, and accelerated aging.

Regulatory and launch support: Alignment to vehicle/part standards, third-party testing coordination, and PPAP production readiness.

Anti-Harmful agent series—making healthy cabin air a material property, not an afterthought. Contact us to design your customized low-VOC, low-odor solution for automotive interiors.

Aqueous, Scavenger of aldehyde and odor

Aqueous, Additives for reducing TVOC in coatings

Aqueous, Additives for reducing odor in coatings