As a team of chemists dedicated to functional additives for automotive interiors, we integrate materials science, interface chemistry, and human factors engineering to create the Touch Agent series—precision-designed to deliver measurable, premium tactile feel.

Why Touch Agent

Tactile feel defines perceived quality: Human evaluation relies heavily on visual and tactile cues. For genuine and synthetic leather, the premium impression is determined not only by the substrate, but more critically by the microstructure and interfacial behavior of the topcoat.

Two core dimensions of touch: Surface feel is a coupled experience of “drag/tack” and “slip/slickness.” Excessive drag feels sticky and heavy; excessive slip feels hollow and insubstantial. The ideal feel strikes a dynamic balance between the two and remains stable across scenarios such as dry/wet hands, temperature-humidity changes, and fabric contact.

Our solution: Touch Agent tactile tuning system

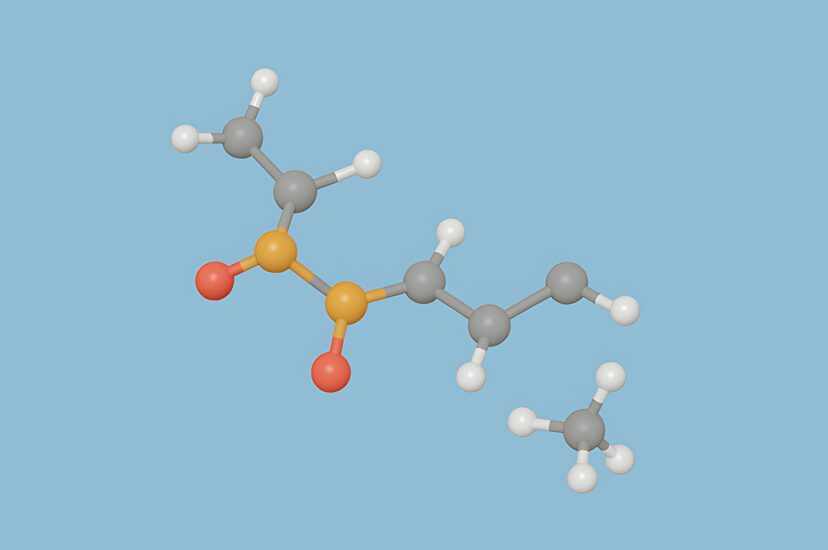

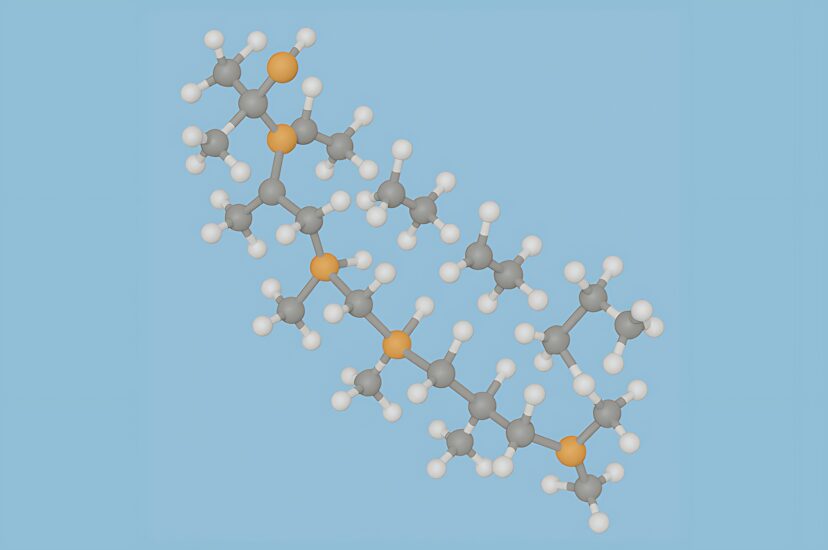

Molecular-level fine-tuning: Functional polymers and low-migration lubricating moieties preferentially adsorb and orient at the interface to build a nanoscale “tactile buffer layer,” raising or lowering the static/dynamic friction window on demand to linearly tune drag and slip.

Surface energy and microtexture synergy: Precisely matches the surface energy of PU, acrylic, and fluorinated topcoats, and works in concert with coating micro-roughness and soft/hard segment morphology to stabilize the finger–surface friction–displacement response.

Programmable feel profiles: Ready-to-use templates such as “silky-smooth,” “soft and dry,” “velvety-warm,” and “fine matte.” We can tune tactile dimensions independently under a fixed optical target (gloss/DOI) to ensure what you see aligns with what you feel.

Key advantages

Low migration, durable feel: Resistant to sweat/sebum, damp heat, and thermal cycling with minimal tactile decay. Non-oily, non-sticky, and keeps the surface clean over time.

Appearance and adhesion friendly: At recommended dosages, does not induce craters/fisheyes and has minimal impact on adhesion and mar/scratch resistance. Low fog/odor, meeting in-cabin VOC and odor requirements.

Waterborne-first: Engineered for waterborne primers/topcoats, balancing wetting, film formation, and interlayer adhesion. Can be post-added and dispersed under moderate shear.

Broad substrate compatibility: Applicable to genuine leather, synthetic leather topcoats, PU clearcoats, ABS, coated ABS, and PC/ABS commonly used in interiors.

Testing and human-factor validation

Zigler tribology mechanism testing: Leveraging Zigler’s tribology and haptic evaluation, we quantify static/dynamic friction gap (μs–μk), spectral response, and shear threshold, building a “tactile fingerprint” database that strongly correlates lab data with finger perception.

Co-creation with OEMs: Collaborations with multiple automotive OEMs translate consumer preferences into engineering targets—defined friction windows and surface energy—enabling data-driven haptic design.

Scenario replication: Validation under dry/wet hands, varying temperature and humidity, fabric/trim coupled friction, and long-term contamination (sweat, sebum, dust), assessing feel retention and cleanability recovery.

Application guidance

Recommended dosage: 1–8% on total formulation. For silky enhancement, start at 1–3%; for soft dry/de-tack profiles, 3–6%; for strong tactile shaping or rough substrates, up to 6–8%. Optimize stepwise to the target drag/slip and appearance limits.

Addition method: Preferably at let-down or as a post-add. Avoid excessive shear and foaming. Evaluate synergy with flow/defomer packages to prevent appearance drift.

System selection: In systems rich in silicone slip aids, choose low-silicone or silicone-free grades to reduce spray sensitivity and adhesion risk. For ultra-low fog/odor programs, select reactive grades to minimize migration and odor.

Process tips: Control application viscosity and flash-off to maintain uniform surface energy. For spray systems, manage atomization pressure and gun distance to avoid local enrichment and feel non-uniformity.

Compliance and standards

Low VOC, APEO-free, low odor; compliant with ISO 12219, VDA 270/VOC, and mainstream OEM in-cabin specifications.

Starting from chemistry, we make touch feel designed, validated, and scalable. The Touch Agent series delivers long-lasting, premium smoothness and refined tactility to automotive interiors—so every touch feels just right.

Waterborne tactile additive for coatings; imparts a waxy, mildly oily feel and improves abrasion resistance.

Waterborne tactile additive for coatings; imparts a silky, low-friction feel and improves abrasion resistance.