As a team of chemists specializing in functional additives for automotive interiors, we translate formulation science into exceptional surface aesthetics and consistent application performance.

Leveling Additives — Flow and Surface Control for Waterborne Coatings

Overview

Amid stricter environmental regulations and growing attention to the safety of manufacturers and end users, waterborne technology has advanced rapidly and become mainstream in automotive interior coatings. However, compared with solventborne systems, waterborne systems still have inherent differences: higher surface tension/surface energy can lead to insufficient substrate wetting and suboptimal flow and leveling, resulting in orange peel, craters, pinholes, and brush marks.

Our Solution

Designed to address the pain points of waterborne systems, our leveling additive series improves wetting and leveling. When incorporated into waterborne coatings, they:

Lower surface tension to rapidly and uniformly wet a wide range of interior substrates (plastics, PU, PVC, artificial leather, composites).

Enhance flow and self-leveling to significantly reduce surface defects and achieve fine films with high gloss or uniform matte.

Improve defect tolerance, mitigating the impact of dust, microbubbles, and minor contamination on film appearance.

Technical Highlights

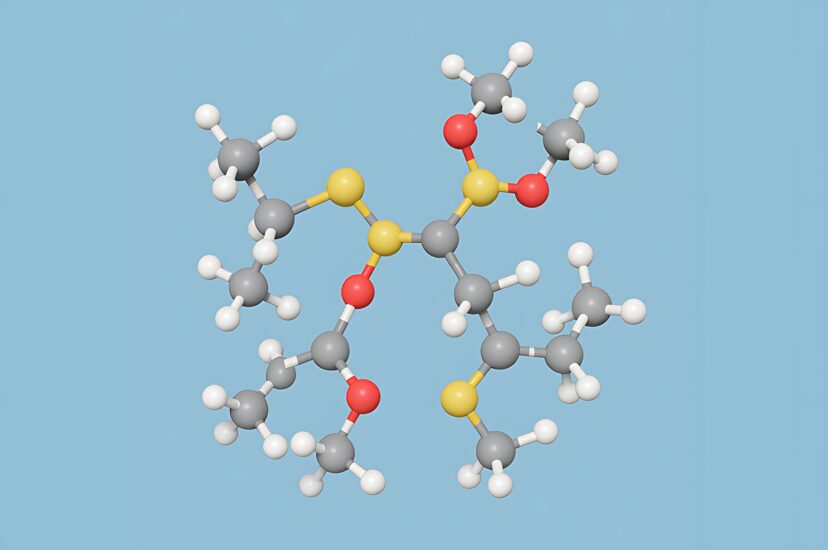

Tailored chemistries: silicone-modified and polyacrylate-based options balance leveling efficiency, recoatability, intercoat adhesion, and low foaming.

Waterborne compatibility: highly compatible with polyurethane dispersions (PUD), acrylic emulsions, epoxy, and hybrid waterborne systems.

Rheology optimization: maintains suitable viscosity while preserving open time for film formation, reducing sagging risk.

Low VOC, APEO-free, low odor to meet sensory and regulatory requirements for automotive interiors.

Performance Advantages

Improved substrate wetting: rapidly reduces contact angle, suitable for low-surface-energy, hard-to-wet substrates.

Higher leveling efficiency: smoother films with fewer orange peel/craters and improved DOI (distinctness of image).

Recoat and adhesion friendly: at appropriate dosages, does not compromise intercoat adhesion or secondary processes such as printing/spraying.

Sensory quality: supports low odor, low fogging (FOG), low VOC, and premium visual/tactile finish.

Application Guidance

Recommended dosage: 0.1–1.0% on total formulation, adjusted per resin system, defect sensitivity, and target appearance (high gloss/matte); start at 0.1–0.3% and increase stepwise.

Addition point: add in the letdown stage or post-add; disperse under medium shear; conduct lab screenings and record the appearance–viscosity window.

Compatibility: evaluate in combination with defoamers and slip agents to avoid overdosing; low-silicone grades are available for spray-sensitive lines.

Quality control: assess leveling grade, DOI, gloss, wetting (contact angle), and defect counts according to relevant OEM interior test methods.

Technical Support

Additive selection and formulation fine-tuning tailored to resin/substrate/application method (spray, roll, dip).

Experimental validation: film drawdown, flow/leveling imaging, contact angle, gloss/DOI, cross-hatch adhesion, and recoatability assessments.

Regulatory alignment: benchmarked against ISO 12219, VDA 270/VOC, and various OEM interior specifications.

Leveling additive series — delivering solventborne-like flow and appearance for waterborne interior coatings while meeting modern in-cabin requirements for low VOC and low odor.

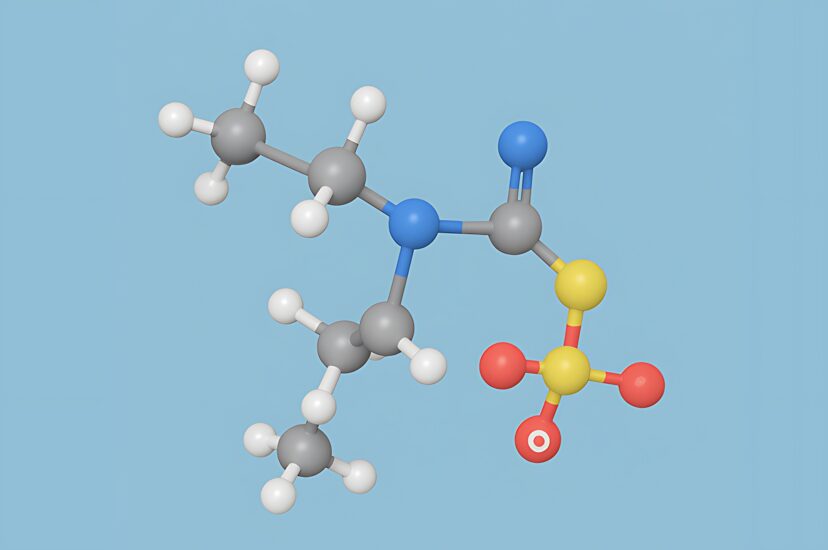

Aqueous, Surface-active auxiliary for coatings, strong leveling properties.

Aqueous, Surface-active auxiliary for coatings, strong leveling and wetting properties.