As a team of chemists dedicated to functional additives for automotive interiors, we turn materials science and interface engineering into a best-in-class Anti‑Squeak solution for seating.

Positioning

Applications: Automotive seats, home sofas, and wrapped parts made of genuine leather, synthetic leather, PU, ABS, and PC/ABS.

Core problem: Creaks and squeaks from polymer topcoats during friction–micro slip–micro adhesion cycles.

Our approach: Tune surface energy and tribology to suppress stick–slip or shift it out of the audible range—eliminating noise at the source.

What sets it apart

Waterborne ready: Designed for waterborne primers/topcoats. Balances wetting, film formation, and intercoat adhesion without changing existing processes.

Broad compatibility: Works on leather/synthetic leather topcoats, PU clears, ABS, coated ABS, and PC/ABS—new build and refinish.

Long-lasting quiet: Stable, low-noise friction profile under repeated loading, thermal cycling, and damp heat—lower peaks, fewer events.

Sensory-safe: Non-migrating, non-oily, non-tacky. Minimal impact on gloss, hand feel, and odor. Supports low fogging/low odor cabin targets.

How it works (chemist’s view)

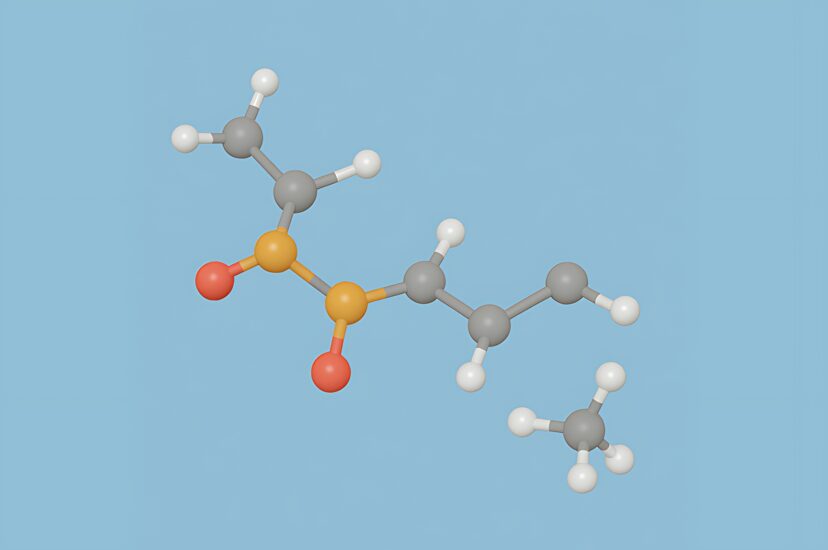

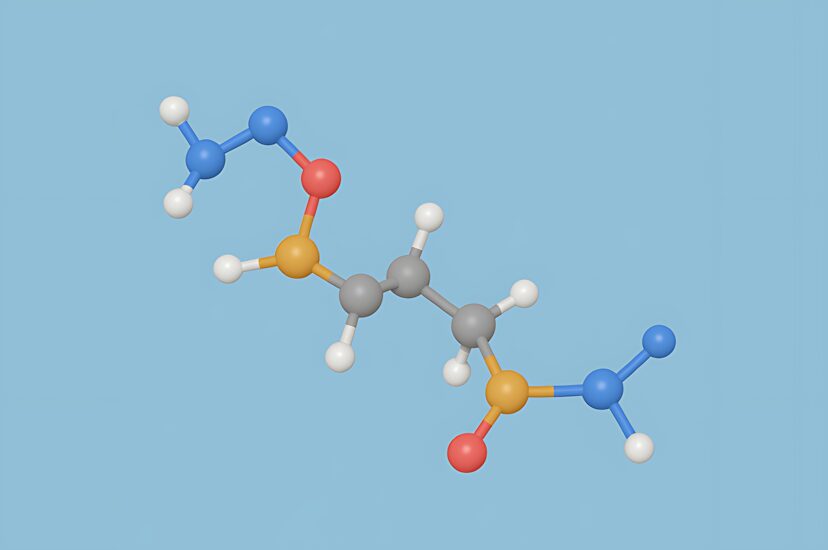

Tribology tuning: Functional molecules adsorb at the interface to form a nano “buffer layer,” narrowing the gap between static and kinetic friction and suppressing stick–slip.

Surface energy matching: Calibrated to leather topcoats (PU, acrylic, fluorinated) and counterfaces (trim panels, apparel fabrics) for stable friction–displacement response.

Synergistic chemistry: Silicone-modified and silicone-free polymers with reactive lubricating units deliver anti-squeak efficacy without sacrificing adhesion, recoatability, or stain resistance.

Key benefits

Ready to use: Effective at 1.0–5.0% on total formula in most waterborne systems. Post-add friendly; disperses under moderate shear.

Appearance and adhesion safe: At proper dosage, maintains adhesion and mar resistance; resists cratering and fisheyes in spray.

Proven durability: Validated by compression/release cycling, thermal shock, damp-heat (40–80°C, 50–95% RH), and multi-material friction tests.

Compliance: Low VOC, APEO-free, low odor. Meets ISO 12219, VDA 270/VOC, and major OEM interior standards.

Application guidance

Dosage: 1.0–5.0% on total formula. Starting points—leather/synthetic leather: 1.5–3.0%; ABS/PC‑ABS: 1.0–2.0%. Optimize by squeak risk and appearance targets.

Addition: Add in letdown or as a post-add. Avoid excessive shear/foaming. Co-evaluate with defoamers/flow agents to prevent appearance drift.

Compatibility: In systems with high silicone slip, select low-silicone or silicone-free grades to reduce spray sensitivity and adhesion risk.

QC focus: Friction noise spectra (ISO/ASTM), OEM squeak/creak ratings, reciprocating friction (μs/μk), gloss/DOI, adhesion/mar resistance, fogging/odor.

Technical support

Selection and customization: Multiple chemistries (silicone-modified, silicone-free, reactive) and tailored friction windows for your coating design and production conditions.

Lab-to-line support: Formulation tuning, spray/roll process windows, objective noise spectrum testing (1–10 kHz), and full-seat rig validation.

Failure analysis: Corrective actions for tack-back in damp heat, dust contamination, fiber transfer, sweat/sebum interference, and long-term stability.

Grounded in chemistry, our Anti‑Squeak additive series delivers enduring silence and premium tactility—so every ride feels calm and refined.

Aqueous, Anti-squeak agent, Waxy touch

Aqueous Anti-squeak agent, Silky touch